Numerical control system: Standard Taiwan SYNTEC system, high stability, high precision.

High-precision spindle: built-in electric spindle structure, spindle bearing adopts imported high-precision angular contact bearing, to ensure the high rigidity and durable accuracy of the spindle, spindle runout ≤2μm.

High performance cast iron: stable structural design, high quality Mihanna cast iron (dense cast iron) overall bed and drag plate, after aging treatment, strong rigidity, good stability.

High-precision feed: the feed axis is fully servo driven, using imported high-precision ball screw bearings, imported high-precision ball screws and guide rails to ensure processing accuracy and long-term accuracy, repeated positioning accuracy of each feed axis ≤3μm.

Bushing structure: can choose without guide bush, fixed guide bush or rotary guide bush cutting mode, to meet the diversified processing requirements.

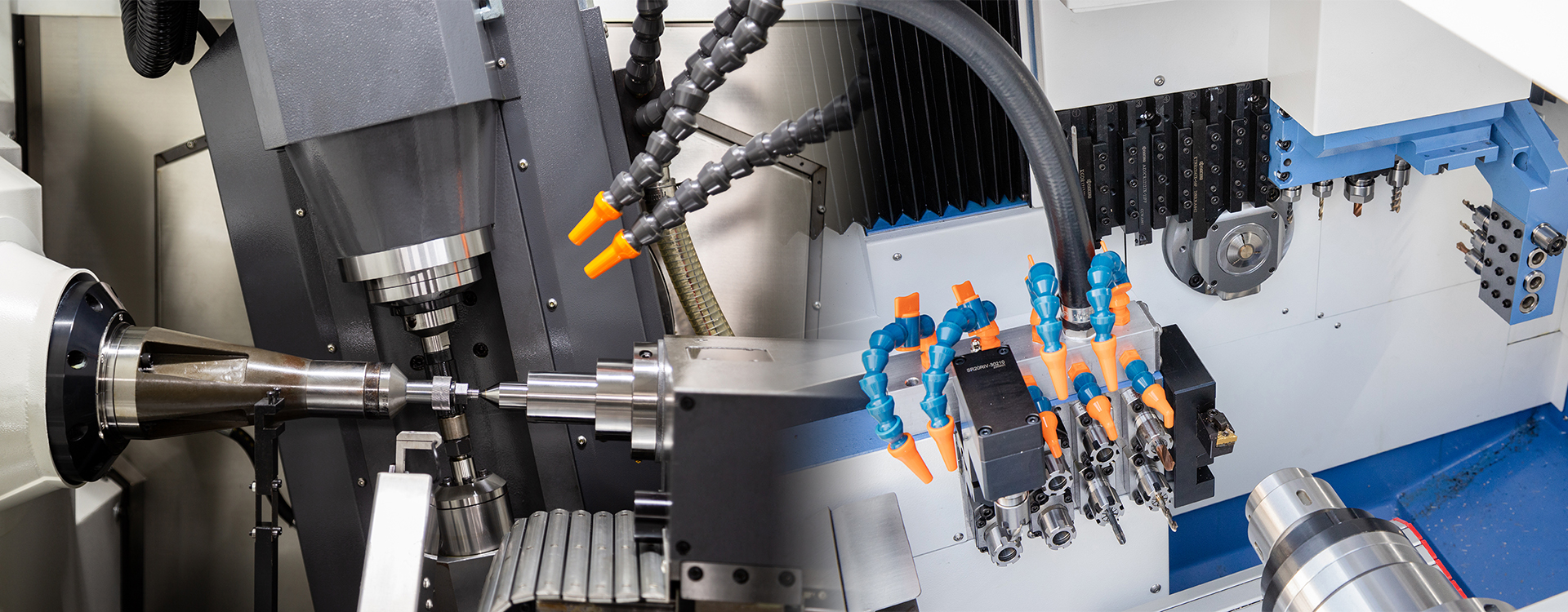

Tool system: horizontal linear tool layout structure, smooth chip removal, compact structure, quick tool change. Equipped with radial power tool, it can meet the complex machining needs of complex turning, milling, drilling and other processes.

Lubrication system: All ball screws and guide rails are lubricated by centralized lubrication system to ensure long-term and efficient operation of the machine tool.

Automation: Through the configuration of automatic feeder, automatic continuous processing can be realized.

Application: Widely used in communication, electronics, automotive, pneumatic and hydraulic, medical, instrumentation, aviation and other industries of complex, small, precise, slender shaft parts processing.

| Main standard configuration | |

| Fixed guide bush | Pneumatic system |

| High precision motorized spindle | Cooling system |

| Main spindle cooling unit | Lubrication system |

| Radial live tool device | LED lighting device |

| Receiving device | LED three-color alarm light |

| Main NC functions | Main optional accessories |

| SYNTEC 8-inch control system | Rotary guide bush device |

| Absolute position servo | High-pressure cooling unit |

| Bus communication | Oil mist collector |

| Hand wheel simulation | Multiple live tools |

| Spindle C axis function | Cut-off detection (mechanical) |

| Live tool rigid tapping | Safety lock |

中文版

中文版 ENGLISH

ENGLISH